Ground Penetrating Radar (GPR) is one of the most specialized and cost-effective inspection methods for the subsurface condition of pavements and bridge decks. Rii has been using GPR since 2002 and has utilized this technology across the country.

Get Comprehensive Results

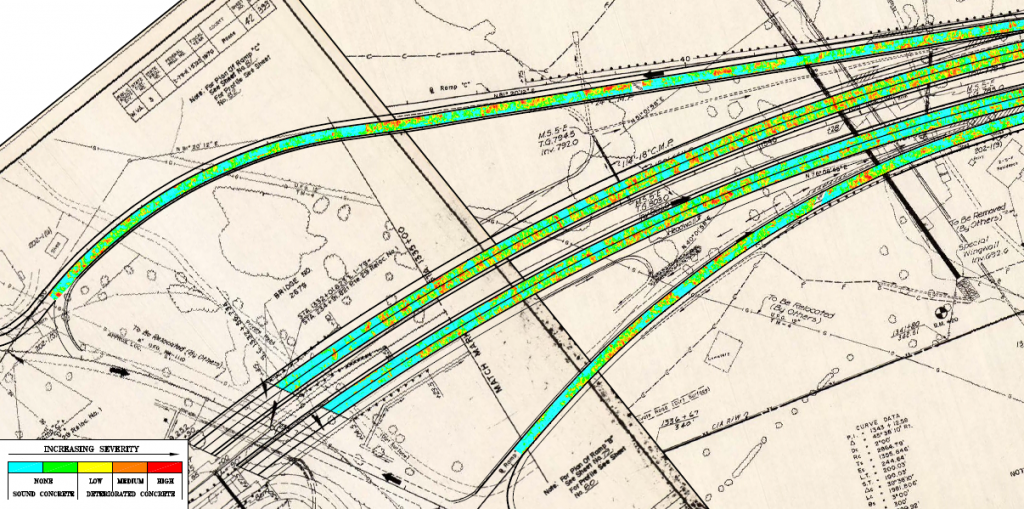

Results typically provide information on bridge deck condition, pavement layer structure, joint conditions, and void areas under the pavements. GPR gives solutions for bridge and pavement rehabilitation projects with information supplied after testing, analysis, and evaluation. It offers positive and accurate delineation of deteriorated boundaries for reinforced bridge decks, accurate and quick confirmation of asphalt overlay measurements, and identification of rebar depth and spacing. GPR can be used to study pavement layer thicknesses, find voids under pavement, evaluate moisture or density variations, detect asphalt stripping zones, and assess the condition of concrete pavements.

Rii maintains the latest equipment and technologies needed to perform the analysis, testing, and evaluation of street and highway pavements and bridge decks. Surveys are performed with multiple scans so that 100% complete structure coverage is obtained. Depending on the objective of the survey, an appropriate antenna(s) is selected to best obtain the desired information in an efficient and economic fashion.

Using GPR with Falling Weight Deflectometer

Pavement thickness survey is one of the most useful applications of GPR to transportation systems for pavement management purposes at the network or project level. GPR can be used to obtain the thickness of pavement layers and the thickness of the aggregate base layer. GPR thickness data are used in the analysis of FWD (falling weight deflectometer) data to back-calculate elastic moduli of pavement layers. The FWD data provide critical information regarding the pavements structural condition. The combination of GPR and FWD are used to select the most effective method of roadway rehabilitation. Pavement cores can be taken to provide additional information on the pavement, including pavement condition, base and subgrade material condition, and can be used to verify the GPR results.

Using GPR with IR

Ground penetrating radar is a well-established and accepted inspection method for accurately assessing the condition of reinforced concrete structures, while Infrared Thermography (IR) is a valuable and cost-effective method for locating concrete delamination/debonding in concrete bridge decks. The combination of IR and GPR is very powerful, maximizing the capabilities of each method and compensating for the limitations. Together, they offer a high degree of accuracy in locating deteriorated and debonded areas and provide a great deal of confidence in the overall deteriorated quantities.

GPR Additional Testing

Rii uses GPR to determine the condition of the concrete and locate reinforcing steel in concrete parapet walls and bridge pier caps. GPR is also used to locate gravesites and Underground Storage Tanks (UST) and detect voids behind Mechanically Stabilized Earth (MSE) walls.

Geophysical Services

We have used GPR for client projects across the nation from New York to California performing pavement condition, geophysical services, and structure condition surveys for their capital improvement projects. Various applications of GPR include:

Bridge Deck Assessment

Continuous Pavement Layer Thickness Measurements

Pavement Structure Evaluation

Concrete Structural Inspection

Rebar Depth Profile

Post Tension Cable and Rebar Locating

Utility Locating

Grave Site Locating

Underground Storage Tank (UST) Locating

Publications

Rii is proud to have research papers about our work in Non-Destructive Evaluation published in various prestigious journals. A sample of our publications can be found below.

Materials Evaluation, Volume 76, Issue 5 – May 1, 2018

Show Publication

This paper describes a thorough investigation of two bridge decks using ground penetrating radar (GPR), infrared thermography (IR), chain drag, crack mapping, coring, and chloride ion concentration measurements. It discusses the use of GPR for the detection of bridge deck flaws at the rein-forcing steel level and the use of IR for the identification of overlay delamination. The GPR and IR results are compared to the results obtained from sounding the bridge decks. The correlation between the damages detected using GPR and IR and the conventional chain drag technique is discussed. Combined together, the nondestructive methods used in this study complemented each other to provide the maximum amount of information and create a more effective bridge deck condition assessment. Infrared thermography was effective in the detection of shallow delamination. Ground penetrating radar detected damage at the rebar level and damage extending upward from the corroding rebar to about 2.5 cm from the deck surface. Unlike chain drag, which detects discontinuities in advanced stages, GPR detected features associated with rebar corrosion, such as high-moisture content and high chloride ion concentrations, in early stages. A comprehensive rehabilitation approach of the two structures is proposed.

The International Journal of Pavement Engineering and Asphalt Technology (PEAT) ISSN 1464-8164, Volume:17, Issue:2, December 2016 · Dec 1, 2016

Show Publication

Premature pavement failures and distresses continue to happen despite significant advancements in pavement technology. This paper reports an integrated approach used to evaluate subsurface conditions of 72 centerline kilometers of a highway pavement, as part of an investigation prompted by premature pavement failures of a recent mill and asphalt overlay project. The integrated approach involved ground penetrating radar (GPR), coring, and laboratory testing, in conjunction with a review of existing falling weight deflectometer (FWD) data, design plans, construction and post-construction documents, and other available data. A visit to the site was arranged to assess the conditions of the overlay and identify the type(s) of distresses which were visible on the pavement surface. GPR data was used to identify contributing factors to the premature surface failures, such as large areas of stripped pavement beneath the new asphalt overlay, and localized areas of wet or moist old asphalt base. Pavement cores provided data to verify the results of GPR Tests. FWD test data was used to determine the resilient moduli of the existing pavement layers. The premature pavement failures in this study were believed to be caused by infiltration of water into the milled surface prior to overlaying, questionable structural integrity of the milled surfaces of old asphalt base material, and de-bonding due to tack coat placement issues. Recommendations based on the findings from this study are included in the paper.

Case Studies in Nondestructive Testing and Evaluation Volume 2, October 2014, Pages 14–26/Elsevier · Oct 1, 2014

Show Publication

Dowels are used in jointed concrete pavements to provide load transfer and improve performance. Misaligned dowels could cause poor joint performance that would lead to pavement distresses. An approach to detect misaligned dowel bars in concrete pavements using GPR is proposed. The paper addresses all forms and combinations of dowel misalignment. Equations were developed to identify each misalignment type, and statistical analyses were performed on major categories for the entire project. A decision on the acceptance or rejection of a dowel bar, a joint, or a pavement section, can be made based on the results of the computations and specified tolerance values.

Construction and Building Materials Volume 26, Issue 1, January 2012, Pages 448–458/Elsevier · Jan 1, 2012

Show Publication

Insulated Concrete Form (ICF) walls are widely used for a full range of building designs including residential, theaters, schools, and hospitals. ICF manufacturers cite several advantages compared to traditional building materials but builders are concerned by honeycombing that may occur during the pouring of the concrete, where gaps are left in the concrete. The development of gaps generally occurs between the foam and the surface of the concrete. Acoustic sounding, a traditional inspection technique to locate voids, would be unsuccessful due to the plastic foam. In this research study, Ground Penetrating Radar (GPR) was proved successful in detecting gaps that developed between the foam and the concrete, voids intentionally created in the concrete, and voids that developed during the pouring operation. Small voids (e.g., less than ¾ in.) were difficult to detect but are not likely to cause any hazard to the structural integrity of buildings. The tests were performed at different stages of concrete curing using both the 1500 MHz and the 2600 MHz antennas. It is shown in this paper that the first void in the concrete was detected at day 7. However the best results were achieved at day 28 of curing. Data analysis has shown the success of the 1500 MHz antenna, but also the limits of the 2600 MHz antenna in the detection of buried voids in ICF structures.

Other Non-Destructive Evaluation Services

Rii provides many comprehensive NDE services to help you evaluate your infrastructure and facility assets. Click here to learn more about the innovative technology we use to facilitate NDE services, and click here to learn more about Rii’s specialized Pavement Engineering services.